In this entry: step-by-step recommendations for restoring the performance of the N53 engine.

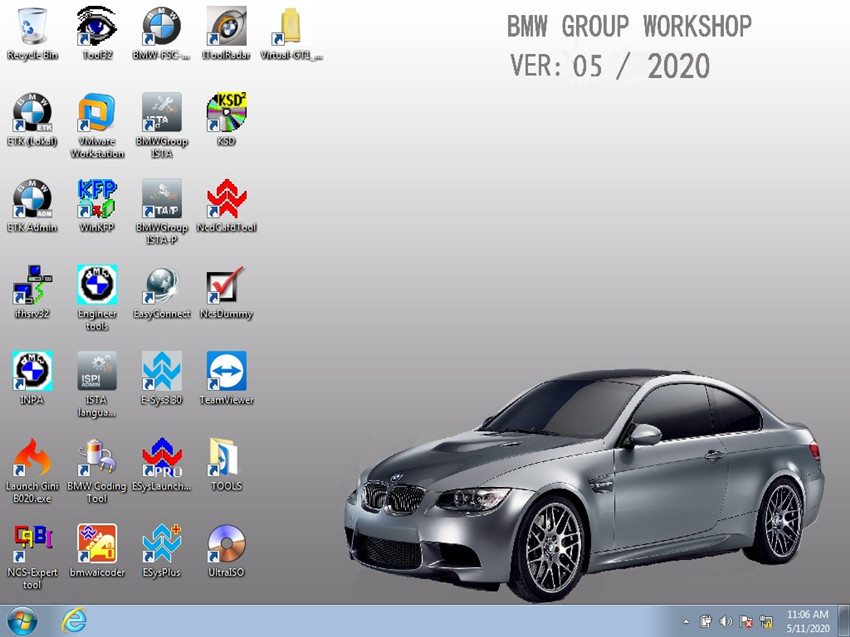

Available diagnostics tool: ISTA D/+

Symptoms: increased fuel consumption, permanent vibration, uneven performance, low-quality idle.

Notes

1. If it is possible, use INPA for F series to diagnose these

engines. Unfortunately, ISTA D/+ gives very limited information, which

can be insufficient in some cases. The manufacturer of the car has

decided to hide the information regarding its problems from the users of

the car.

2. In this entry, the following case is described: no error messages

in the DME error message memory (or there is a 12C401 error message if

the NOXEM is installed), but the performance of the engine is

unsatisfactory. In situations, when the error messages are recorded in

the DME error message memory, use the option “Calculate test plan” of

ISTA D/+ and prevent the obvious problems at the first hand.

3. In addition to the ISTA D/+ tool, you will need also ELM 327

adapter with the required software to read the Misfire counters, which

are reported only in OBD Mode 6 (and are not available in ISTA D/+).

Stage 1. Restoring the Stratified charge

Make sure, if the engine uses a Stratified charge. If a Stratified

charge by some reason is not used, all symptoms, mentioned at the

beginning of this entry, will be typical for the performance of the

engine – the engine works in an emergency mode. To make sure that the

engine uses a Stratified charge, follow here.

If the engine uses a Stratified charge stable (for a longer period of

time, a positive result confirmed during several following driving

sessions), move to the next tests.

If the engine does not use a Stratified charge, at first the use of it should be restored. How to restore a Stratified charge?

a) delete the adaptations of the engine and create new ones, as

described here. Deleting of adaptations will exclude a range of possible

hidden problems from the list of possible problems: insufficient

performance of CO catalytic converters, the uneven performance of the

engine, incorrect injector adaptations, etc. If the Stratified charge is

restored – move to the next tests. If it does not, continue the

check-up.

b) the most typical reason why the Stratified charge is not used:

contamination of the NOx catalytic converter is above the norm.

Unfortunately the F series vehicled do not record any error messages in

DME in this situation (there are no appropriate error messages intended

for F series!). To solve this problem, perform the desulfation session

of the NOx catalytic converter as described here.

If the desulfation session is successful (the voltage of the Lambda

probes is 1.80 .. 1.90V and increased fuel consumption is observed),

check the usage of the Stratified charge after desulfation session,

driving with speed 60 .. 90km/h.

In the desulfation session is unsuccessful (the voltage of the Lambda

probes still is around 2.00V during desulfation session, it means,

Lambda = 1.00) and also the increased speed (till 140km/h) does not help

to activate the desulfation session, make sure that the NOx system is

functioning at all.

Disconnect the NOx sensor for a moment, start the engine. The

following error message should appear immediately: ”CD8510: Lost

communication”. If this error message does not appear – obviously, the

DME software has been “upgraded”: some “benefactor” has tuned off the

NOx system. In this case – at first, the stock software has to be

restored.

If the error message regarding the NOx system appears, we can assume,

that the software is correct. In this case, try to increase the driving

speed to 140km/h and maintain it for several minutes to start the

desulfation session. Don’t forget to fill the fuel – the fuel tank has

to be full for at least 50%. If also this does not help, it is very

possible, that the OEM NOx sensor has a hidden defect (more info here).

If you wish, you can send the NOx sensor to us for the check-up (more

info here).

If it’s not possible to drive with such high speed (till 140km/h), the following option is possible:

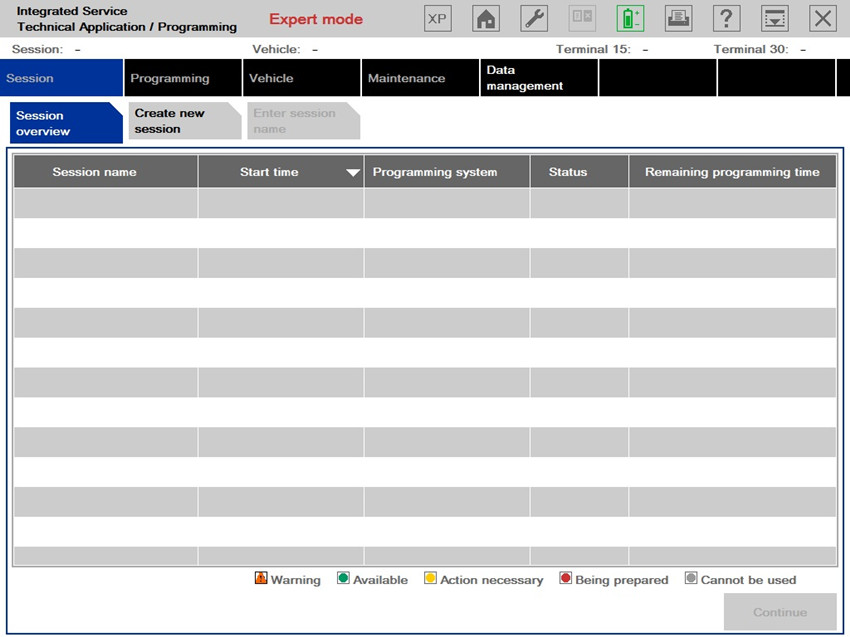

install the INPA for F series, loader 3.700 MSD87 for N54 (will be necessary for NOx converters management);

install the NOXEM on your car.

In this case, please, follow the recommendations of the procedure

step by step as described here, if the INPA diagnostics tool is used.

Stage 2. Restoring even performance of the engine

c) if you have reached this step, obviously, a Stratified charge (at

least for a moment – several motor hours) was restored. It’s good news.

Drive as even as possible for several motor hours, allow the engine to

create new adaptations of fuel & other systems. Evaluate the result.

If the uneven performance (shivering) of the engine can be felt,

continue checking with:

spark plugs. The spark plugs of these engines have to be replaced

after each 20 .. 30.000km. Very important – only appropriate spark plugs

of NGK have to be installed! More about the common problem regarding

the spark plugs read here and here;

ignition coils. Unfortunately due to the constructive defect, the

resource of the ignition coils is quite limited. Several ignition coils

may need to be changed even after several tens of thousands of km. More

about this problem read here. If you see that the ignition coils are

oily, have black “lines” on them, their “pipes” are cracked – the

ignition coil has to be replaced. Install Bosch or NGK ignition coils –

they are more sturdy and will serve for a longer time than others;

if the spark plugs are in good technical condition (or replaced) and the ignition coils look perfect, evaluate Misfire counters.

d) Evaluation of Misfire counters. You will need an ELM 327 adapter with the required software. How to use ELM 327, read here.

At first, evaluate the mechanical efficiency of the cylinders to make sure that all injectors work more or less correct:

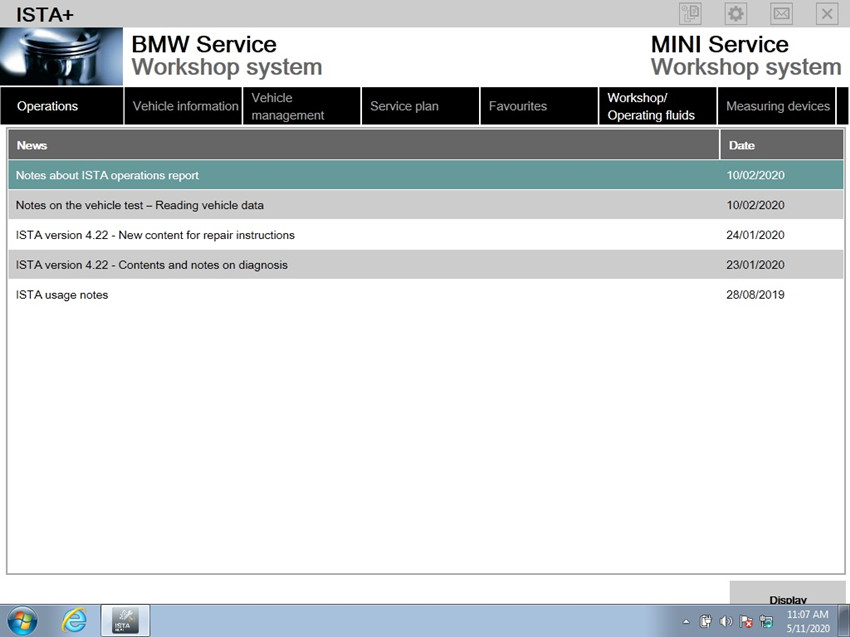

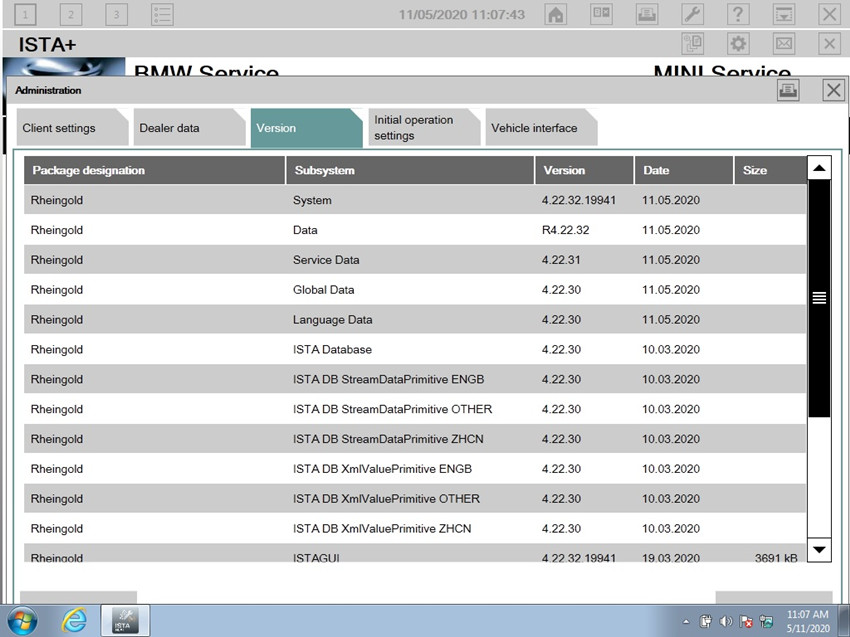

open ISTA D/+, identify the car

in the section of the Vehicle info, choose DME and press ”Call up ECU functions”

in the section of Diagnosis scan choose “Operational smoothness values”, mark all cylinders, press “Read status”.

If Rough run data of all cylinders fit in a range of -0.500 .. +0.500

(except the moments, when the engine shivers), move to the inspection

of the Misfire counters. If the indication of the mechanical efficiency

of any cylinder is negative and reaches over 0.500: the injector of this

cylinder leaks in idle and has to be replaced.

Allow the engine to run in idle and after some time (not turning off

the engine) read the Misfire counters. An increased number of misfires

will indicate the damaged cylinder.

Typical apportionment of the “guilty” components:

90%: ignition coil;

7%: spark plug;

3%: injector.

To identify the damaged component, you can use a “swap” principle –

swap the possible culprit with the next cylinder. If the problem

“moves”, when the misfire counters are read repeatedly – the “guilty

one” has been found!

In this stage, you have to reach even the performance of the engine in idle and when driving evenly.

Remember – after replacing the injectors (if it’s necessary) it has

to be encoded, repeated re-adaptation of the engine has to be performed.

Note: in Stratified charge mode, the engine is more “whimsical”, it

means, the misfires appear faster than in Homogeneous mode. The spark

needs max power to ignite the fuel. Every tiniest damage of the ignition

system or even slightly incorrect beam of the injector causes misfires.

So, don’t be surprised, that when the engine switches to a Stratified

charge, some cylinder starts to misfire. You can find the culprit,

reading Misfire counters.

If increased vibration is observed directly for the cold engine:

start the cold engine, open the “Operational smoothness” values of cylinders, using ISTA D/+ ;

at the moment when the unevenness of the cylinders start (wideband

Lambda probes start to work), observe the mechanical efficiency of

cylinders. If the mechanical efficiency is strongly negative (more than

-0.500), the injector of this cylinder leaks and has to be replaced.

As a result of the previously mentioned procedures, you should reach that:

the engine regularly uses Stratified charge;

the performance of the engine is even – no short-term shivering

(misfires), no permanent vibration (consequences of leaking injectors)

are observed.

Unfortunately, due to some specific problems (for example, reduced

performance of the CO catalytic converters, “floating” of the parameters

of the injectors, reduced performance of the NOx catalytic converter,

stability problems of LPFP/HPFP pressures, air-tightness of the intake

manifold, etc) is possible, only using INPA.

Accordingly – if in some modes the engine still runs unevenly or the

Stratified charge “disappears” after some time and does not restore, you

have to install

BMW ISTA Software and perform additional tests.